How a desktop 3D printer can help a company saving cost?

In general, if a company is developing product, the normal procedure should be like this.

1. Design 2. making sample 3. redesign & discussing with sample supplier 4. making second sample 5. decide to mass produce.

If with 3D printer, the procedure will be

1. Design 2. making sample by 3D printer 3. redesign 4. making second sample by 3D printer 5. decide to mass produce.

It looks like the procedure is not different, but the main different steps is making sample. Because ID engineer can print out their design by 3D printer, the material is PLA or ABS filament, start to printer after work, and get 3D product on the next day. It can save time for waiting making mold of sample. It helps company to develop new product faster than competitors.

Besides, even though the precision is not as high as CNC machining center, but for the cost is much cheaper. If company can save this cost, and share this saving for engineer, who doesn't like it.

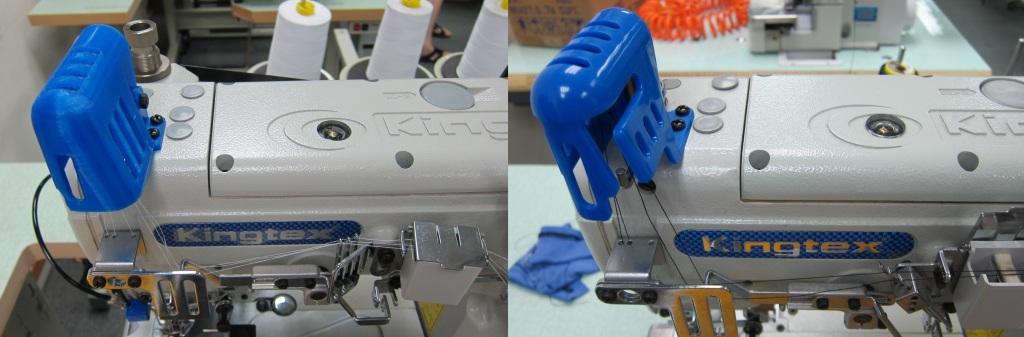

Taiwan Famous sewing machine maker,kingtex Company,using Mastech 3D printer to make company more competitive.

Can you see different between below 2 machines?

The blue cover is making by 3D printer. The blue cover is making by mass produce.

RD engineer use MASTECH 3D printer to print first sample, after confirm design, redesign, and then use mold to mass produce. It is saving several weeks and more than thousands money cost.

The blue cover is making by 3D printer. The blue cover is making by mass produce

If company owner wants to save this cost and share to you, what would you say? YES!!YES!!YES!!